Organizational information

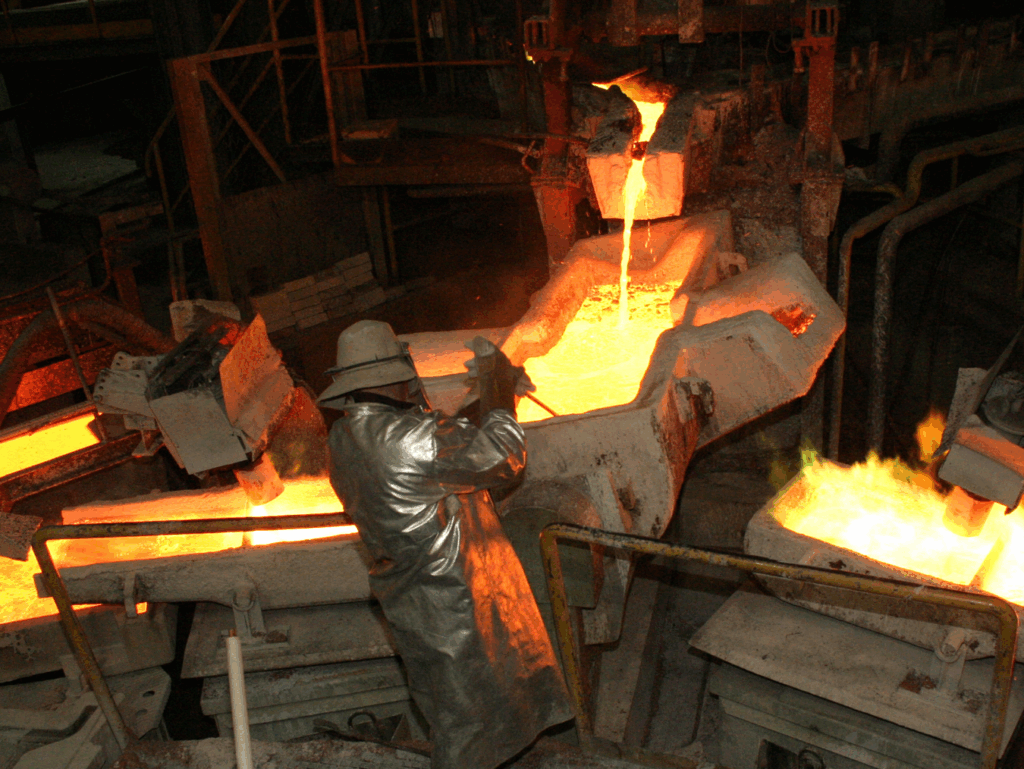

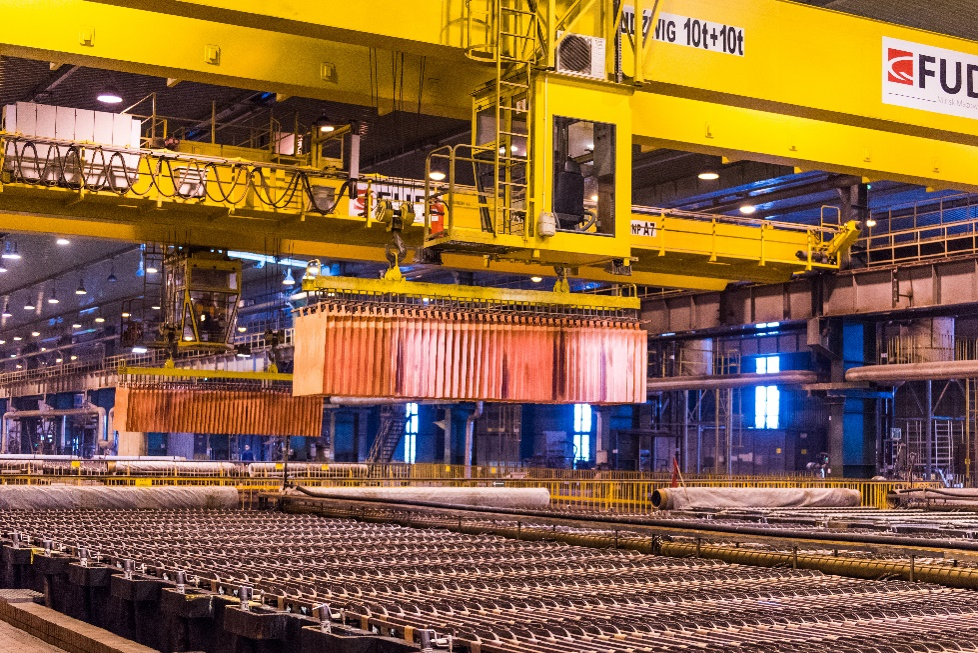

Participants will be able to get acquainted with the technology and the process of extracting and processing copper ore in KGHM Polska Miedź S.A.

According to the adopted schedule of the Congress, technical visits will take place on June 4, 2025 from 8:00 to 13:00.

For organizational reasons and to maintain the safety of people staying in KGHM, the number of participants is limited. Therefore, the order of applications will decide about participation in the visit you chosen. Individual visits will take place in groups of 8 ÷ 15 people

Application form

|

# |

Plik |

Rozmiar |

|---|---|---|

|

1 |

453kB |

Places of technical visits